Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

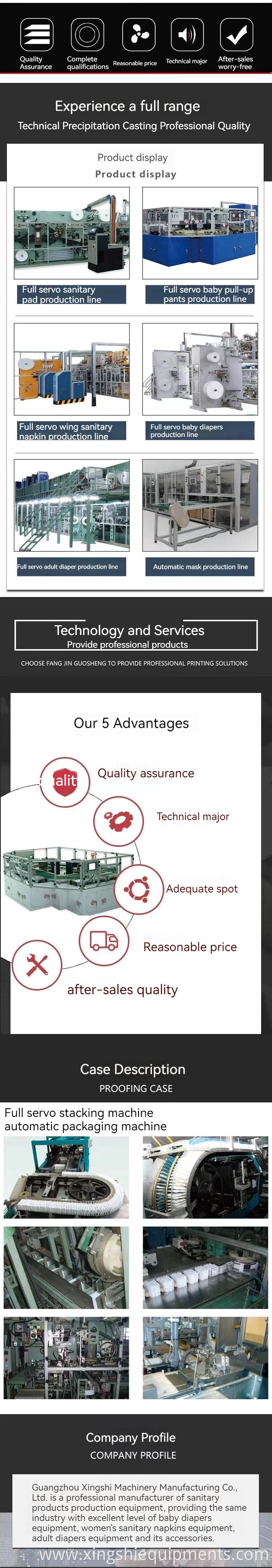

Brand: Xingshi Machinery

Place Of Origin: China

Status: New

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Core Component Warranty Period: 1 Year

Warranty Period: 1 Year

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Branch: Xingshi Machinery

Stabilize Speed: 300pcs/min-1000pcs/min

Power Supply: 380V50HZ

Installed Power: 300KW

Product Size: ≥98%

Device Size: 30M*11M*4M

Device Weight: 68吨

Productivity: 10000sets/month

Transportation: Ocean

Place of Origin: Guangzhou, China

Supply Ability: 100000sets/month

Port: Guangzhou Port

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CIF,EXW,DDP

Product Categories : Women's Health Products Production Line > Sanitary Pad Production Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.