Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

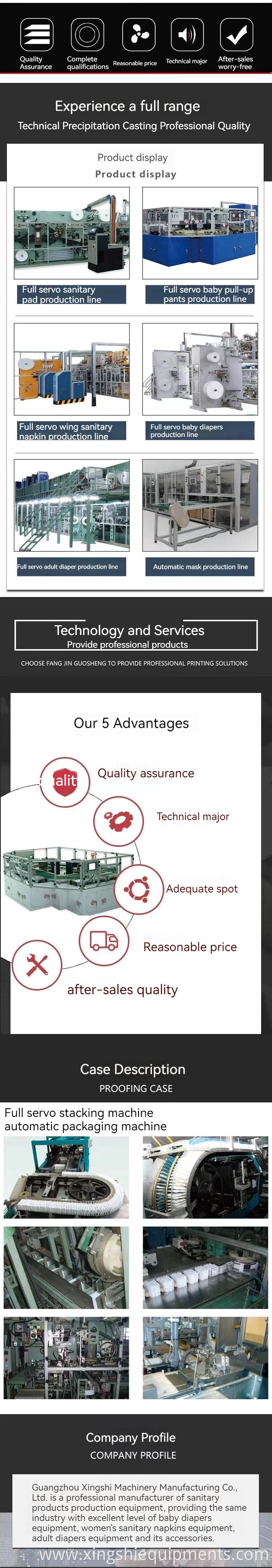

Brand: Xingshi Machinery

Applicable Industry: Home Use, Retail, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Status: New

Product Category: Diaper Machine

Processing Type: Cutting Machine

Place Of Origin: China

Certification: Ce

Productivity: Other

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: New Product 2020

Design Speed: 1000 pcs/min

Product Size: small, medium, large, plus

Machine Size: 40Mx9.0Mx4.5M (according to product structure)

Equipment Weight: 95 tons

Warranty Period: 1 Year

Core Component Warranty Period: 1 Year

Power Supply: 380V50HZ

Productivity: 100000sets/year

Transportation: Ocean

Place of Origin: Guangzhou, China

Supply Ability: big quantity and high quality and supply on time

Certificate: CE,ISO

HS Code: 8453200000

Port: Guangzhou

Payment Type: L/C,T/T,D/P,D/A,Paypal,Others

A high efficiency diaper making machine is a state-of-the-art manufacturing equipment designed to produce diapers quickly and efficiently. It incorporates advanced technology and automation to streamline the production process and increase productivity.

Here are some key features of a high efficiency diaper making machine:

1. Speed and productivity: These machines are capable of producing diapers at a high speed, significantly increasing production output. They can manufacture a large number of diapers per minute, ensuring quick and efficient production.

2. Automated processes: The machine is equipped with automated systems to handle various processes, such as material feeding, cutting, folding, and sealing. This automation reduces the need for manual labor and ensures consistent quality throughout the production process.

3. Precise control and adjustment: High efficiency diaper making machines come with advanced control systems that allow for precise adjustment of various parameters, such as diaper size, shape, and absorbency. This flexibility enables manufacturers to produce a wide range of diaper products to meet different customer requirements.

4. Waste reduction: These machines are designed to minimize material waste during production. They optimize material usage and ensure accurate cutting and sealing, reducing the amount of scrap or rejected diapers.

5. Quality control: High efficiency diaper making machines incorporate quality control mechanisms to detect and eliminate defects during production. They may include sensors, cameras, or other inspection devices to monitor and ensure the quality of diapers being produced.

6. Energy efficiency: These machines are designed to be energy-efficient, reducing energy consumption and operating costs. They may incorporate energy-saving features, such as efficient motors, power management systems, and insulation to minimize heat loss.

7. Easy maintenance and troubleshooting: High efficiency diaper making machines are designed for easy maintenance and troubleshooting. They may include user-friendly interfaces, diagnostic tools, and self-cleaning mechanisms to simplify maintenance tasks and minimize downtime.

Overall, a high efficiency diaper making machine offers manufacturers the ability to produce diapers at a faster rate, with improved quality control and reduced waste. It helps meet the increasing demand for diapers while optimizing production efficiency and profitability.

Product Categories : Baby Hygiene Product Production Line > Baby Diaper Production Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.